Published, 29.08.2022

Using digital pre-op planning as a marketing tool

Dr. Peter Keppler’s practice for surgical orthopedics and traumatology (Ulm, Germany) discovers unanticipated benefits of mediCAD®

First, there was the question of documentation. How could the practice perform the legally mandated pre-op planning in a way that ensured each step in the process remained consistent and trackable? Documentation problems inevitably arose in the use of conventional pencil-and-template planning. Lost or illegible drawings are just two examples of commonly encountered issues. To resolve this situation, Dr. Keppler decided a good ten years ago to start using digital planning software. Today, however, digital pre-op planning provides benefits that extend far beyond electronic digital documentation. Greater precision and reliability, as well as time-savings in every operation, are now even more important.

The solution, mediCAD Classic® from Hectec GmbH of southeastern Germany, has proven its value time and time again in each of these areas. Moreover, Dr. Keppler has found the program structure to be highly intuitive and much easier to use than comparable products. Users of the software at Dr. Keppler’s practice in Ulm required neither a manual nor any training to use the software efficiently.

The decision to use mediCAD was made easier by its compatibility with the GEMED-PACS system, economical long-term financing, and the guarantee of ongoing maintenance and support.

Centralized implant database

In contrast to earlier planning methods that relied on folders with 3-D templates, mediCAD® has the world’s most extensive database of implants. This database contains 450,000 templates of all sizes from 105 international manufacturers, and is updated every month with new and updated implant systems. In the rare instance that an implant is missing, it is added to the database at no charge. Thanks to this database access, simulating several variations of an operation (with a variety of implants) is very straightforward, making it easy to find the best possible solution. In fact, each pending operation can be analyzed more thoroughly in the same amount of time that it would take to plan just one variation using a radiograph, vellum, and templates. Single-variation plans that once took half an hour can now be completed in about two minutes. All planning data can be transferred directly to the hospital’s own PACS system, where it can be referenced during surgery. The overall process can be completely paperless, with each step automatically saved and documented in an audit-proof manner.

Faster and more precise

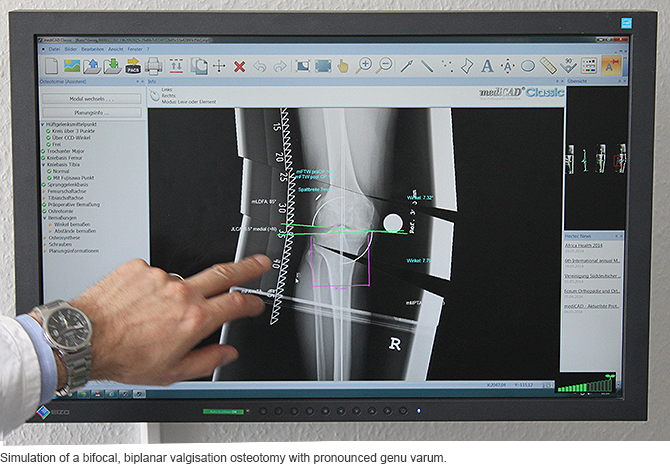

Digital planning with mediCAD® combines time savings and greater precision. One example is the automatic indication of anatomies in a plan that are outside the normal range. The program identifies these immediately so the surgeon can determine how he or she wishes to proceed. Particulary in knee joints, precision is a critical factor in determining how an implant will perform over an extended period of time. Even defective axis positions are clearly detected and documented – an important point for potential malpractice cases.

The ability to measure both legs and depict them side by side is one of the solution’s specialties and plays an important role during leg operations. With this feature, the surgeon can easily use the “healthy” leg as a reference for the correction.

Finally, the program has proven to be an outstanding training tool for medical students. Several variations of an axis correction can be planned when exploring “what-if” scenarios.

More patients

In addition to improving the quality of surgery and significantly reducing planning time, the use of cutting-edge processes is becoming an important factor for patients when they are selecting a surgeon. The doctors in Ulm have found that patients are increasingly seeking several opinions before deciding on the type of operation and selecting a surgeon. Digital planning allows the physician to explain each step in the planning process to the patient while referencing easy-to-understand images on the screen. This approach conveys a sense of security, builds trust, and makes the patient’s decision easier. Dr. Keppler points out that “this is very valuable, particularly with defective axis positions and deformity corrections. In these cases, the patient isn’t under quite as much stress as those who have had accidents, so they tend to be very interested in participating in planning on the computer.” The significant increase in the number of deformity corrections performed at the Ulm practice (about 80 in 2013 and an anticipated 120 this year) is another result of this type of patient involvement, according to Dr. Keppler. At the same time, the system generates documentation that can be used as an effective response to possible future claims of lacking or insufficient information before the operation. Such litigation is unfortunately an increasingly common phenomenon.

“Without mediCAD®, it would be virtually impossible for us to operate as a practice,” says Dr. Keppler in summing up his experience. The osteotomy module for the lower extremities and the “before-and-after” simulation for the patient are the most important functions. The physician goes through two to three plans together with the patient during each consultation. In total, this comes to about 400 planning sessions per year. Approximately 80 percent of these sessions relate to deformities and corrections of the lower extremities.

At a glance