Knee and hip joint replacements are the two joints most frequently replaced with an artificial joint in Germany. However, endoprosthetic treatment of the shoulder joint has also increased significantly in recent years.

increased significantly in recent years, as today’s modern implants, better understanding of the joint, improved surgical planning options, and optimized surgical technique are delivering ever better results. The shoulder function and the associated quality of life of many patients can be approximately restored if the surgery is performed in a specialized manner at the right time. In Germany, for example, an average of around 25,000 artificial shoulder joints are implanted each year.

While preoperative planning is required by law for operations on the knee and hip, there is as yet no planning obligation in shoulder endoprosthetics. Nevertheless, two-dimensional digital preoperative planning in shoulder endoprosthetics is already widespread and established in Germany and Europe and is almost standard practice.

Dr. Wolfgang Vogt, MD, orthopedic specialist at the Orthopedic Specialty Center (OFZ) and head of the three-member “Upper Extremity, Shoulder and Elbow” team, talks to us about the fundamentals of shoulder arthroplasty, the future of digital planning, and why classic planning on templates is no longer in keeping with the times.

mehr lesen

Shoulder arthroplasty has recently evolved significantly. Ever more sophisticated prosthesis models are achieving ever better results. An annual rate of about 200,000 hip endoprostheses and 170,000 artificial knee joints

knee joints are compared with 25,000 shoulder prosthesis operations per year, but the trend is clearly upward.

*Source: www.bvmed.de/de/technologien/bewegungsapparat/schulterprothese-nicht-zu-lange-warten

mehr lesen

mediCAD Hectec GmbH:

Dr. Vogt, although there is no legal basis for mandatory planning, two-dimensional digital planning of orthopedic operations in shoulder arthroplasty is already widespread and established in Germany and also in Europe.

is already widely used and established in Germany and Europe. Digital planning in hip and knee arthroplasty, on the other hand, has long been mandatory by law. Why is this requirement not met in the planning of

not yet established for planning shoulder endoprostheses?

mehr lesen

Wolfgang Vogt, MD:

This is completely inexplicable to me because the scale distortions in the shoulder area are immense in X-ray images on transparencies. Because of the images

the different body postures during the X-ray exposures, the

the X-ray images, the resulting considerable size deviations due to the distance to the X-ray film, and the resulting lack of accurate representation of the

bones in the required standard planes, precise size and angle measurement is practically impossible.

is practically impossible. In addition, we now live in

an ever-increasing digital world, planning with normal one-dimensional X-ray images is no longer up to date!

mediCAD Hectec GmbH:

Why do you plan digitally when you don’t have to?

Wolfgang Vogt, MD:

I have been planning all my shoulder endoprosthesis operations digitally for over 10 years, since 2007 to be precise, in order to have reproducibly accurate plans available intraoperatively that I can rely on and in which the planned sizes then also correspond to the actual conditions. This gives me a fundamental sense of security when operating and helps me to avoid common mistakes in shoulder endoprosthetics, such as overstuffing by choosing too large an implant.

mehr lesen

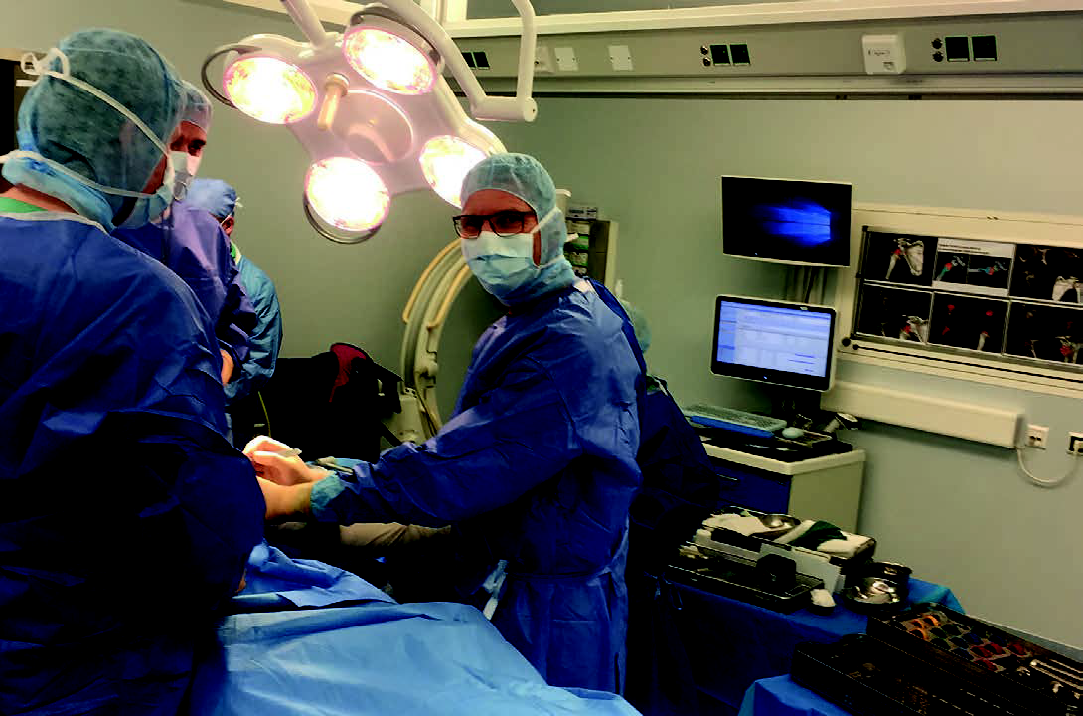

The humeral head resection with the necessary osteophyte resection as well as the positioning of the glenoid component is much easier for me and can be performed more accurately with better knowledge of the size relationships. In the end, this helps the patient because the result in terms of mobility of the shoulder joint replacement and survival time of the prosthesis is better. In addition, I observe a reduction in OR time, the more precise the planning, the less time the patient spends in the OR.

In the past, I tended to plan the prosthesis alignment, but with the ever-improving planning software packages and the availability of digital prosthesis templates, also in the shoulder region, the implant sizes can now be planned exactly. This reduces the time-consuming task of determining the prosthesis sizes intraoperatively with various trials, saves time and is therefore highly effective and efficient.

mehr lesen

mediCAD Hectec GmbH:

How would you try to convince a colleague who still plans traditionally to use digital planning software?

Wolfgang Vogt, MD:

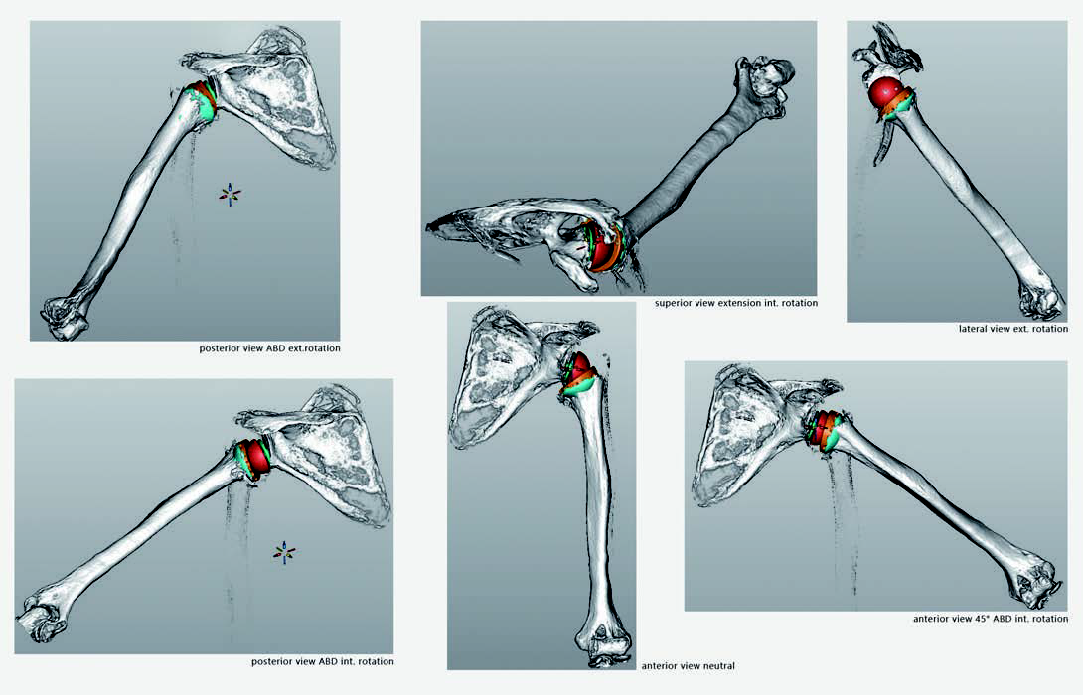

I would perform a digital animated 3D shoulder endoprosthesis planning with him, including determination of the impingement-free mobility by ROM analysis, and then take him with me to the operating room to show him how the surgical procedure is simplified by better knowledge of the anatomical conditions. The possibility of skipping otherwise necessary surgical steps (e.g., sizing of the implants) nevertheless leads to a more precise operation with shorter operating time. The reduction in operating time in turn benefits the patient, e.g. through less blood loss, less risk of infection or less anesthesia time. At the same time, the surgeon also works more economically. Of course, the surgeon also has the planning time before the operation, but here he is alone, without the entire surgical team (from the float to the anesthesiologist), which is otherwise involved in the surgical procedure.

mehr lesen

mediCAD Hectec GmbH:

In your opinion, what are the prerequisites for making digital planning mandatory in shoulder arthroplasty as well?

become mandatory by law?

Wolfgang Vogt, MD:

Difficult question, the legislator and the health insurance companies see many things divergent to the people concerned. On the one hand

mandatory requirements are made that have to be met, but on the other hand, the increased expense for this is not

reimbursed within the framework of the DRG or KV system. A digital planning system costs money that a clinic or practice would have to invest to make planning possible. However, this money comes from a “different

pot”, namely from the EDP budget. And in order to invest this money, savings have to be made elsewhere. In my

In my opinion, this “thinking in pots” must stop and the end result must be seen by the patient. Through higher

quality automatically leads to higher customer satisfaction, which in turn leads to higher profitability.

with it. This is especially true when you take into account the costs that arise if a less precise operation with a possibly misplaced prosthesis results in prolonged follow-up treatment, incapacity to work, need for care, or even a revision operation after the operation. or even a revision operation if necessary.

mehr lesen

mediCAD Hectec GmbH:

How does digital planning differ from planning with templates and what are the advantages?

Wolfgang Vogt, MD:

As already mentioned, our environment is becoming more and more digital, also in medicine. Copies and transparencies are no longer

contemporary!

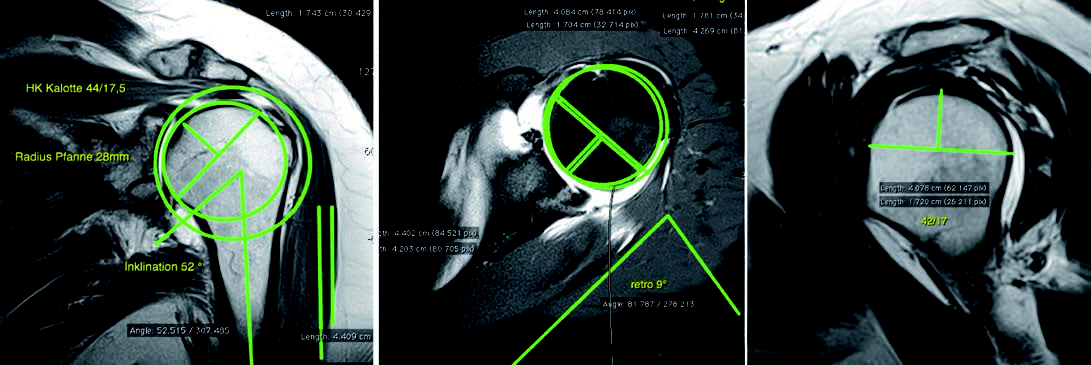

A modern orthopedist no longer has X-ray images on slides. I explain to the patient his arthritis changes in the digital X-ray. In case of significant bony defects, I measure them directly in the digital image via

DICOM calibration with the character measurement program and explain to the patient in the X-ray or better in the

cross-sectional MRI or CT, these wear-related changes, including the corresponding consequences. In the case of a planning system connected to the PACS, the implant can also be shown at the same time and, if necessary

and, if necessary, it can be explained that, for example, bone augmentation at the socket will be necessary to

will be necessary to achieve a correct joint reconstruction. This gives the patient confidence, because he sees that you are

that his pathology is being dealt with, that the operation is being planned intensively, and that he is being prepared for it.

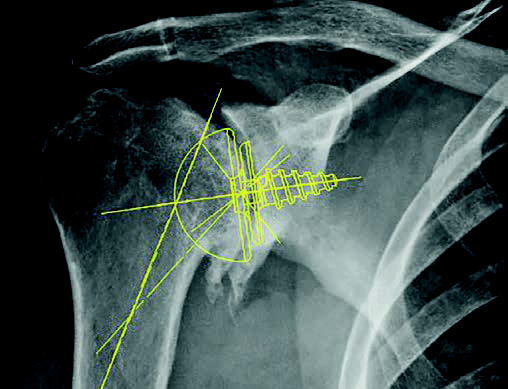

My patients have been receiving individual planning from me for about three years now, and they receive

immediately after the operation, several post-operative X-ray images corresponding to the planning,

on which they can see that the operation performed with the prosthesis position achieved corresponds to the planning,

especially in terms of positioning and in 95% of cases also in terms of implant size. This gives patients

patients a tremendous sense of security. After all, every patient wants to know “how it went” at the post-op visit. If you

surgeon can say “everything went according to plan without any complications, at the end of the operation I tested your joint in all the important positions, it was

I tested your joint in all important positions, it is stable and moves harmoniously,” and can back this up with pictures and documents.

documents, this gives the patient confidence and satisfaction.

mehr lesen

Another important point for preoperative digital planning is the successive reduction of the surgeon’s operating time, because this is a relevant part of the operation and must be included in the calculated operating time. Digital planning, like every step of an operation, has a learning curve, and with more experience this happens correspondingly faster. For example, I need between 5 and 10 minutes for normal shoulder planning. For a 3D planning with a 3D joint reconstruction including animated 3D ROM analysis and viewing of the joint from different angles, as it is currently possible with the mediCAD® Shoulder 3D software, I currently still need about 30 minutes.

mehr lesen

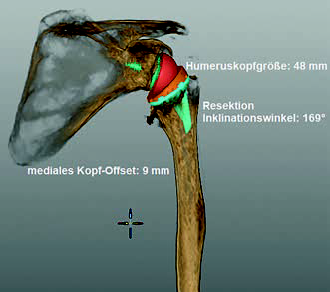

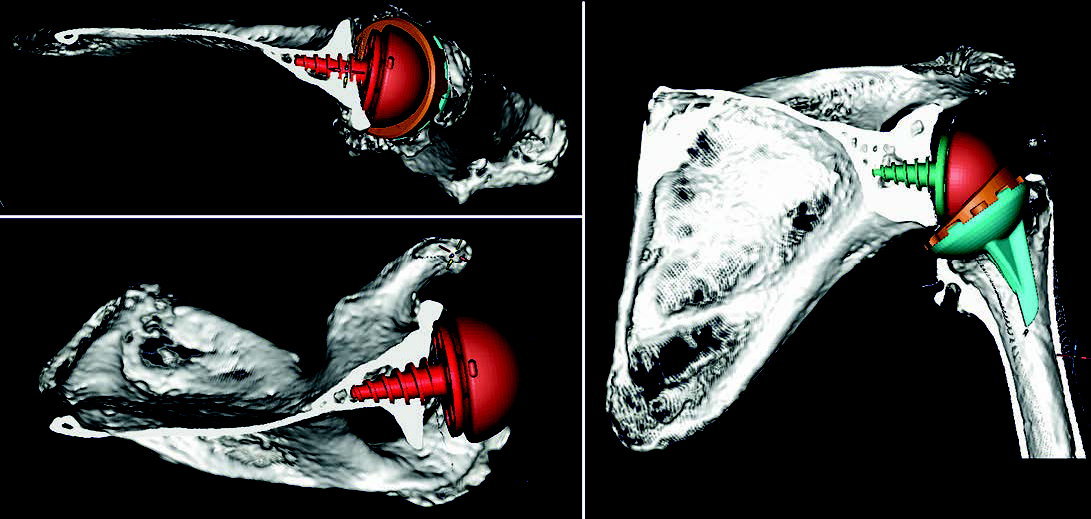

The 3D-reposed joint in particular, especially in the case of the inverse shoulder TEP, with a visible implanted prosthesis and the possibility of viewing it from any angle in space, is currently still something exciting new for me with many variables that are still possible. Currently, I am trying to figure these out in a playful way to find the previously known optimal prosthesis position, check it against new possibilities and validate it, ideally taking into account soft tissue stress ratios due to length changes. In the beginning, I needed an hour for the same planning steps, now, as already mentioned, it is 30 minutes, i.e. the learning curve shows that here, too, the pure planning time is reduced with increasing experience, with even better results.

mehr lesen

mediCAD Hectec GmbH:

Do you use the software for every upcoming operation or only for particularly difficult and complicated cases?

How do you plan for “standards”?

Wolfgang Vogt, MD:

I think it’s the most normal thing in the world to do planning before an operation. After all, every builder gets a plan

architect before he starts building a house. First the input plan, later the more precise work plan. Who would still build a house today without planning? Most modern architects even simulate a

3D room planning with a virtual tour of the house to get a feeling for the space. It is similar with us. Thereby

it does not matter whether it is a particularly “complex case” or rather a routine operation. In my opinion

I think that even the “simple” cases are the most difficult. The patients have even fewer limitations and less pain than the advanced arthroses with significant bone and soft tissue defects. These types of

pathologies by surgery to improve and satisfy them in the long term is therefore more difficult and needs maximum

precision. Therefore, I do not understand why many of my colleagues demand or

do. I think every case should be planned, this also brings routine for the supposedly simple cases and

safety for the then more difficult cases. When I try something new in my daily routine, I also don’t start with the

difficult things!

mehr lesen

Wolfgang Vogt, MD:

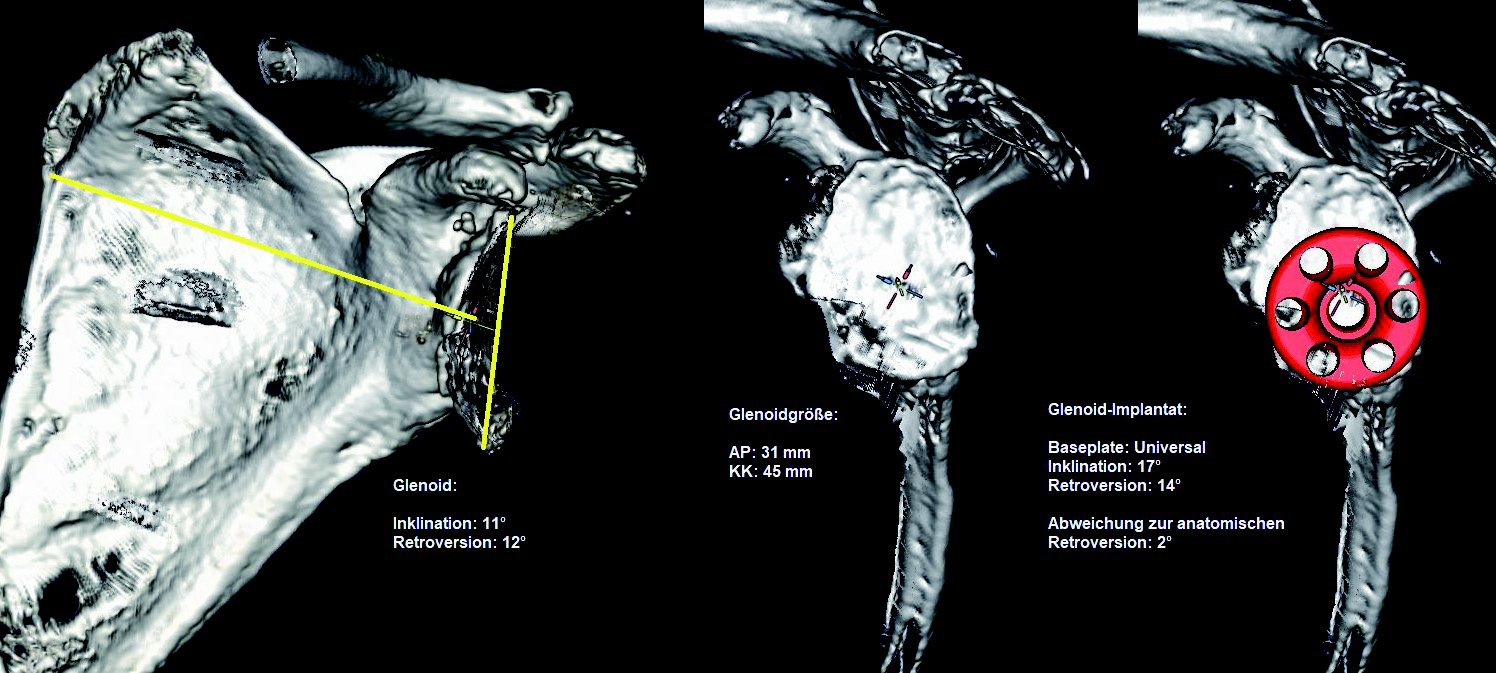

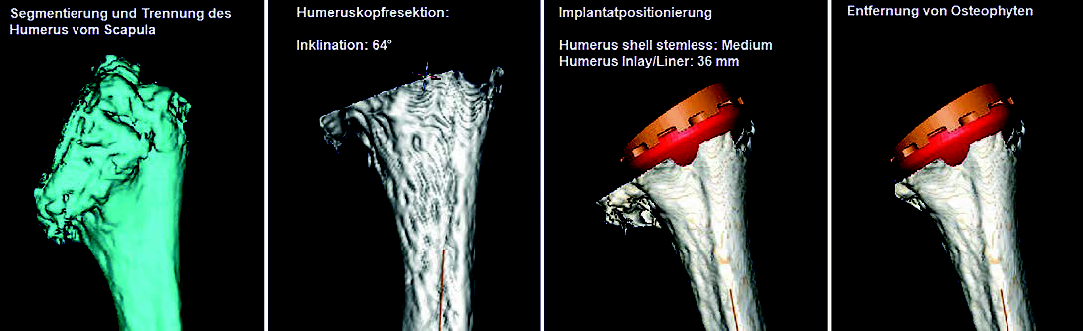

For every upcoming surgery, I try to make at least one digital 2D plan, ideally even a 3D plan.

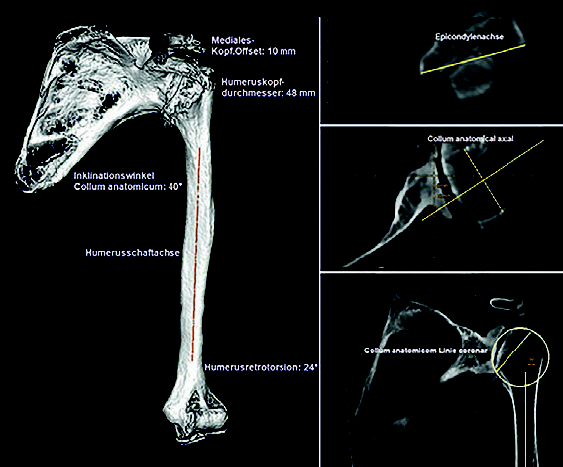

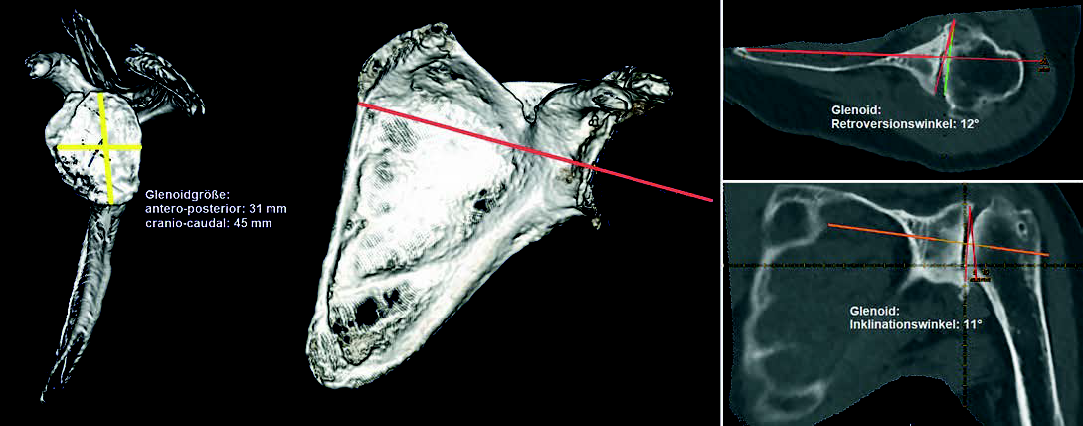

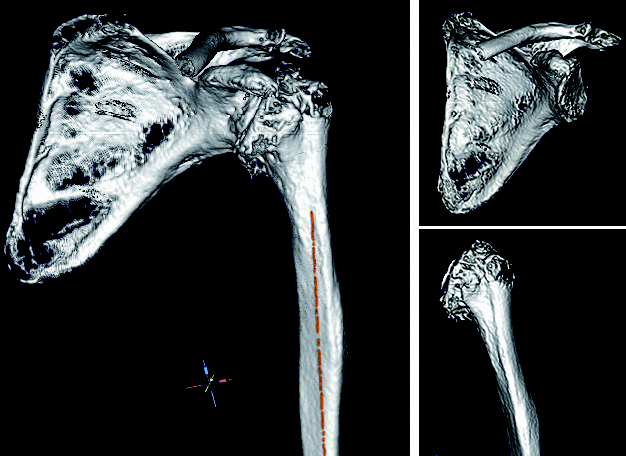

even a 3D plan. However, 3D planning is based on CT images, and unfortunately I do not always have a suitable CT with the appropriate thin-slice resolution and dimensions (entire scapula and epicondyles), because many patients only have an MRI with them, which usually does not show the end points of the affected bones that are actually required, and they assume that this is sufficient.

and assume that this is sufficient. However, digital 2D planning is also possible on the basis of an

MRI, but with significantly more limited information than 3D planning with reproducible reference planes in the scapula planes and humeral axes.

Therefore, I am currently in the process of developing a mediCAD® CT protocol together with our local radiologists.

to explain the advantages of 3D planning with determination of the humeral retrotorsion by capturing the epicondylar axis. The problem with this, however, as is often the case, is reimbursement. The required CT is associated with additional

additional work for the radiologist, which is not reimbursed, so that the performance of the more complex CT is a “goodwill” service of the radiologist.

service of the radiologist, on which we are currently still dependent.

I had already mentioned the “potty thinking” here before. The practice or the clinic has additional costs with regard to the investment in planning software (EDP budget). By this investment could be saved if necessary elsewhere

costs could be saved elsewhere (OP cost pot). The radiologist, however, naturally does not profit from a shorter OR time.

mehr lesen

However, patients may not be charged additional costs by either the hospital or the surgeon. By law, all costs of prosthetic surgery are included in the DRG system with a flat rate. Preoperative planning costs for the surgery, however, are not included as an item in the calculation. Also private insurances often refuse to recognize this completely outdated service code GoÄ 3321 (3D shoulder TEP planning analog, value with 3.5-fold increase 20,38- Euro, for approx. 30 minutes planning time of a specialized experienced surgeon) for the preparation of a construction plan for a large orthopedic aid. However, the patient expects from his surgeon an optimal diagnosis, clarification and presentation of his actual condition as well as a planning of the upcoming surgery. In my view, however, optimal preoperative planning in accordance with the state of the art is a quality criterion and should be regulated by law as a matter of urgency.

mehr lesen

mediCAD Hectec GmbH:

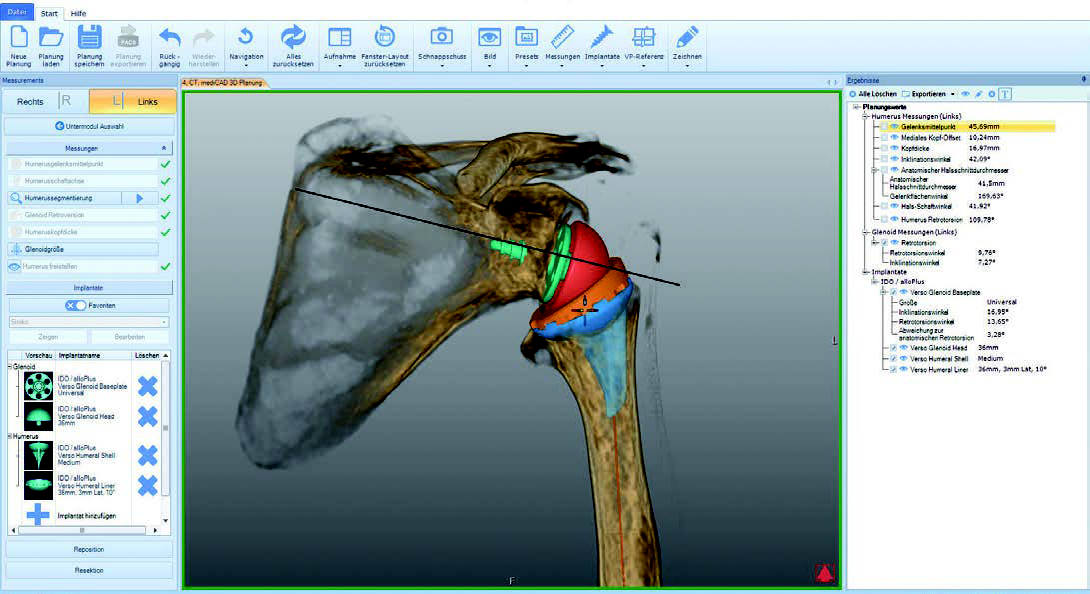

You are already using the mediCAD® Shoulder 3D software module from mediCAD Hectec GmbH for your work. The software is brand new and has just been launched on the market. Since when have you been using the new module?

And why did you decide to use an animated three-dimensional planning software with ROM motion analysis? Wouldn’t 2D have been sufficient? And why mediCAD®?

Wolfgang Vogt, MD:

I have been using mediCAD® Shoulder 3D since March 2019. I have been planning 2D digitally for more than 10 years, which was

innovative.

The shoulder joint, like every joint in the body, consists of two joint partners moving against each other, which are

are connected by soft tissues and only certain sizes and positions of the joint replacement ensure, even after surgery, the regular, satisfactory for the patient, long-term function. If it is possible today with the

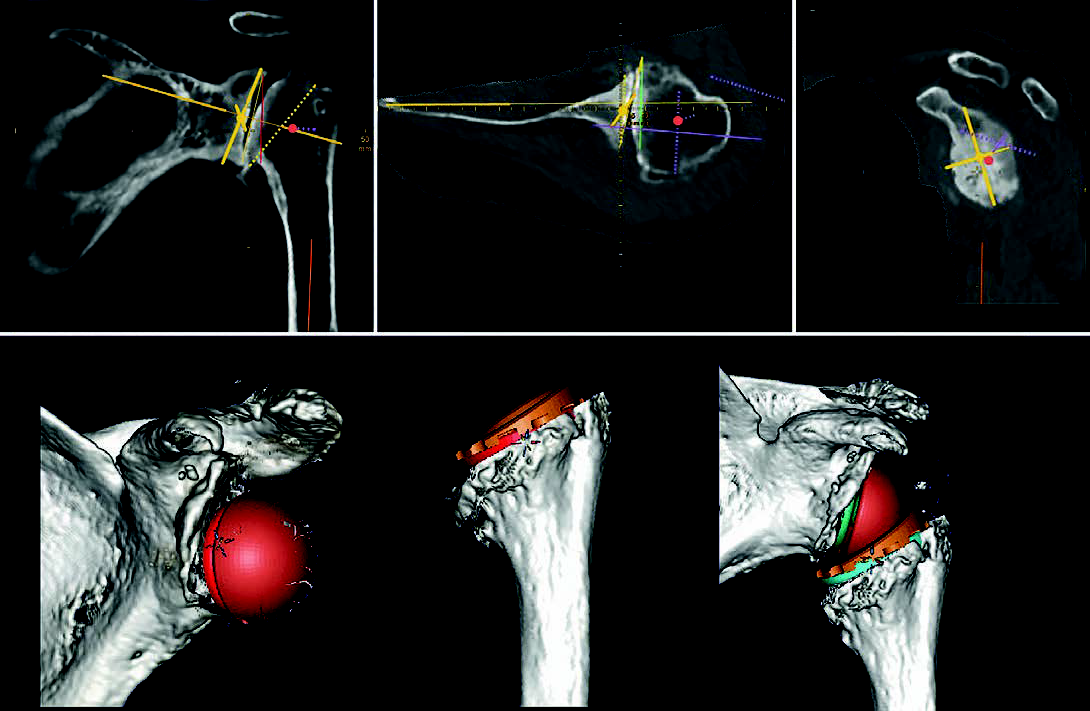

mediCAD® animated 3D joint planning with ROM analysis, there is nothing more obvious to me than to simulate and test these optimal prosthesis sizes and their alignment, including the possible technical freedom of movement from a bony and implant-related point of view, in advance and without the risk of surgery.

in advance without any surgical risk. Then I can go into the operation relaxed and with a clear concept and a good conscience towards the patient.

conscience towards the patient.

mehr lesen

mediCAD Hectec GmbH:

Endoprosthetics is also always associated with revisions. What advantages do you see in the use of digital planning

planning software with regard to revisions?

Wolfgang Vogt, MD:

In my experience, shoulder prosthesis failures and required revision surgeries can basically be divided into two

categories: First, so-called “early failures” that occur up to about two years after the primary surgery.

such as secondary RM ruptures with overstuffing, instability, stiffness, persistent pain,

limited ROM and weight-bearing capacity, the cause of which is predominantly due to incorrect primary implantation

(size selection and orientation of both glenoid and humeral components). And the second category are the

“Late failures” who need to undergo revision treatment after about 10-20 years after primary surgery due to further joint wear, PE diseases or trauma cases such as periprosthetic fractures.

For me, more precise surgical planning, especially with the even more visually vivid animated ROM 3D planning in the shoulder region, leads to more precise primary implantation with significantly better average results and

presumably reduced revision frequency.

However, with regard to the aforementioned “early failures” in misimplanted shoulder prostheses, revisions are

the complexity of revision surgery, often with an unclear outcome, despite digital planning, revisions will only lead to

to better results to a limited extent in the future. Revision surgeries are more difficult than initial surgeries and are often avoided. From the surgeon’s side, precisely because of the complexity and uncertain outcome, and also from the patient’s side,

because of another long pain phase, new surgery and rehabilitation. For revisions after 10-20 years, however, detailed

planning is immensely helpful and highly recommended.

mehr lesen

In my opinion, mediCAD® is the most modern planning software available on the market. Only a few other manufacturers (e.g. Materialise, Medacta, Blue Print, etc.) also offer combined humerus and thus joint planning. mediCAD® does this individually according to the surgeon’s movement specifications, while some others do so with standardized movement patterns for functional analysis, but without ROM movement analysis. In addition, compared to its competitors, mediCAD® is independent of the prosthesis manufacturer. This therefore enables comparative prosthesis planning between different products and implant manufacturers. And without a doubt it can be said that mediCAD® has access to one of the largest, most comprehensive and well-maintained implant databases, continuously growing and regularly updated. All implant manufacturers have the possibility to provide their implant data, so that these can be entered.

mehr lesen

Another advantage of mediCAD® Shoulder 3D is that the surgeon himself (and not some engineer of the implant manufacturer) can perform the segmentation of the CT data set according to his medical experience and interpretation of the CT images. In addition, the creation of a 3D model and the possibility of subsequent planning of the glenoid and humerus individually one after the other are possible. Also, full joint planning after reduction of the joint with implanted components are features that I, as a physician, would not want to miss. And of course the 3D ROM analysis of the reduced joint with the prosthesis in place.

mehr lesen

mediCAD Hectec GmbH:

Are there functions that you still miss in the software, but which in your opinion are absolutely necessary for optimal planning?

planning?

Wolfgang Vogt, MD:

The current disadvantage of mediCAD® Shoulder 3D is that there are still no PSI templates that can help to implement the precise preoperative planning intraoperatively as a result of the planning. Various studies show

that the use of a joint planning software and the resulting patient-specific guide/instrument can increase the implantation accuracy, with a deviation of < 5° and < 2 mm. Own

experience with CT post-op position checks shows that the deviation from the planning by planning alone without

without using a guide is about twice as large as when planning and using a PSI guide. However

I know that mediCAD Hectec GmbH is already working on a solution and I am confident that in the near future the PSI function will also be available in mediCAD®.

Another desirable tool for me as a user would also be a standardized ROM analysis motion of the

Glenohumeral joint, derived from the typical movements of daily life (apron grip, neck grip,

grip to the opposite shoulder), which should be retrievable one after the other from the neutral zero position to determine the required range of motion of the glenohumeral joint and to identify areas of conflict (notching

subacromial impingement), disconnected from the “parasitic” motion in the scapulo-thoracic joint, which also

contributes to shoulder function.

mehr lesen

mediCAD Hectec GmbH:

You are also currently working on a book article for shoulder orthopaedic surgeons that deals with digital preoperative planning

for the shoulder and also highlights why two-dimensional planning is not sufficient in shoulder joint orthopedics. Can you briefly summarize what brings you to this conclusion? Why is

in your opinion, 3D planning is absolutely necessary for the shoulder?

Wolfgang Vogt, MD:

Correct implant positioning has a significant impact on postoperative functional outcomes, from

instability, wear, and secondary soft tissue problems with rotator cuff lesions to prosthesis failure with prosthesis loosening. For this reason, preoperative prosthesis planning is essential. The pure

two-dimensional planning on the conventional X-ray is not sufficient for the shoulder. For exact positioning, three-dimensional planning based on CT data, with standardized reference planes as the starting position for reproducible planning, offers a good possibility that extends to preoperative dynamic simulation.

for the movements relevant and required in daily life. The weak point of this bony planning still lies in the non-consideration of the soft tissues (delta tension, contractions), which must be evaluated intraoperatively by the

The weak point of this bony planning is still the lack of consideration of the soft tissues (delta tension, contractions), which must be evaluated intraoperatively by the surgeon, with a possible adaptation of the hardware planning to the soft tissue situation. However, this requires an experienced surgeon. In order to implement this preoperative hardware planning, patient-specific instruments are already available from some prosthesis companies, mainly on the glenoid side, but also partly on the humerus side.

but also partly on the humerus side. I am convinced that in the future, the clinical and imaging studies that are undoubtedly

necessary to test these modern planning methods and the resulting surgical techniques, will be able to

the resulting surgical techniques, will be able to demonstrate the overall economic benefits and, in particular, the advantages for the patient.

mediCAD Hectec GmbH:

Dr. Vogt, thank you very much for your support.

mehr lesen

At the OFZ Weilheim – Garmisch – Starnberg – Penzberg, approx. 750 shoulder operations are performed per year, including approx. 100 prosthesis operations. The orthopedic specialist center is a supraregional orthopedic group practice with four practice locations, five cooperating clinics and its own outpatient surgery center as well as a total of 13 specialists in orthopedics, orthopedic and trauma surgery and surgery. The OFZ team “Upper Extremity, Shoulder and Elbow” consists of three colleagues specialized in these sub-specialties: Dr. Wolfgang Vogt, Dr. Johann Wasmaier and PD Dr. Stefan Buchmann.

Dr. med. Wolfgang Vogt Specialist for Orthopedics at the OFZ in Garmisch, “Upper Extremity, Shoulder and Elbow” Team

mediCAD Hectec GmbH

Since 1994 mediCAD Hectec GmbH is engaged in software solutions for orthopedic surgeons. The goal is to enable efficient and safe planning of joint operations in all aspects, digitally, in clinics as well as in practices.

In 1999, mediCAD Hectec GmbH was the first company in the world to provide a software program that enables the complete preoperative planning of a joint replacement to be carried out professionally in a digital environment with just a few inputs/clicks. With the solution mediCAD®, the company sets an innovative milestone in the support of surgical orthopedics, worldwide. Through automatic archiving of all required information and a continuous traceability of findings, surgical preparation and aftercare, mediCAD® offers the ideal possibility for an optimally prepared, professionally performed and audit-proof documented operation, with correspondingly recorded aftercare.

Through close cooperation with the leading companies in medical technology and the successful use of mediCAD® in over 3,500 clinics worldwide, mediCAD Hectec GmbH, with around 50 employees, is already one of the “global players” in the field of medical software solutions.

mehr lesen