Lorem ipsum dolor sit amet, consetetur sadipscing elitr, sed diam nonumy eirmod tempor invidunt ut labore et dolore magna aliquyam erat, sed diam voluptua. At vero eos et accusam et justo duo dolores et

Veröffentlicht am, 28.08.2022

St. Franziskus Hospital in Köln-Ehrenfeld

Die digitale Planung von Operationen ist aus der Orthopädie nicht mehr wegzudenken – allein schon wegen der damit verbundenen automatischen, vollständigen Dokumentation. Auch ist die Qualität deutlich höher als bei der Planung mit Filmen und Schablonen, hinzu kommt eine erhebliche Zeitersparnis. Dennoch führen nicht alle digital geplanten Operationen zu einem für den Patienten oder den Operateur zufriedenstellenden Ergebnis. Die neue Möglichkeit, am Bildschirm drei- statt wie bisher zweidimensional zu planen, verspricht einen großen Gewinn. Die 3-D-Planung gestattet es, alle mechanisch-geometrischen Parameter exakt einzubeziehen. Patientenindividuelle Prothesen werden damit greifbar.

Digitale OP-Planung in 3D

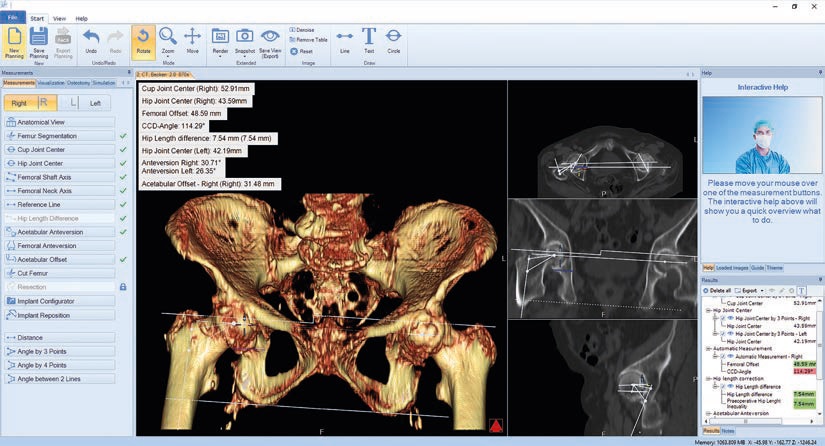

Die Klinik für Orthopädie I im St. Franziskus-Hospital in Köln-Ehrenfeld plant bereits seit 2006 die gesamte orthopädische Prothetik digital. Als zweidimensionales Planungswerkzeug hat sich die Software mediCAD® der Firma mediCAD Hectec bewährt, die das Programm seit 1994 kontinuierlich weiterentwickelt. Über 3.000 Klinken und orthopädische Praxen weltweit nutzen es. Die digitale Lösung berücksichtigt alle Planungsmethoden, dokumentiert alle Vorgänge rechtssicher und deckt alle orthopädischen Operationsgebiete ab – von Hüfte über Knie und Wirbelsäule bis hin zu Fuß- und Sprunggelenk. mediCAD® ist zertifiziert und weltweit als Medizinprodukt zugelassen. Grundlage ist eine Implantat-Datenbank, die die Artikel von mehr als 140 Herstellern enthält. Neben Implantaten findet der Operateur in „mediCAD®“ auch ein umfangreiches Sortiment an Osteosynthesen zur Planung. mediCAD Hectec bietet zusätzlich zur klassischen bewährten 2D-Lösung nun auch die entsprechenden 3D- Modul Komponenten an: mediCAD Hip® 3D, mediCAD Knee® 3D und mediCAD Spine® 3D sind bereits auf dem Markt, die Planungssoftware-Module für Schulter, Fuß sowie eine mediCAD® web-basierte Lösung folgen Anfang 2018.

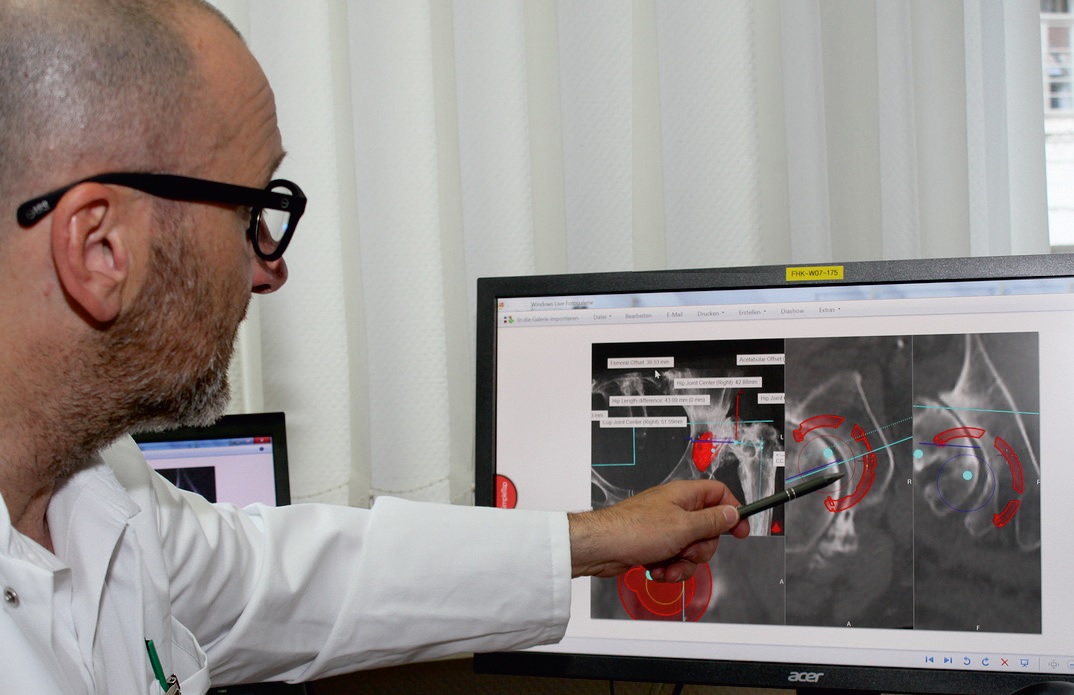

Das St. Franziskus-Hospital in Köln setzt nun seit geraumer Zeit auf die dreidimensionale Planung bei Hüftoperationen mit mediCAD Hip® 3D und plant auch bereits den Einsatz des ganz neuen Moduls mediCAD Knee® 3D.

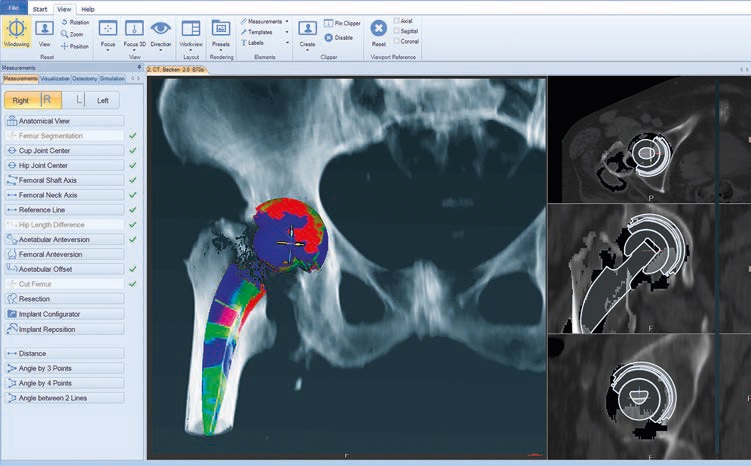

Für den Chefarzt Dr. Klaus Schlüter-Brust steht der Gewinn an Präzision und damit die höhere Sicherheit an erster Stelle. Gleichzeitig ist die Software so anwenderfreundlich und selbsterklärend aufgebaut, dass auch neue Kolleginnen und Kollegen damit sehr schnell sehr gute Planungen erstellen können. „Nach drei gemeinsamen Planungen ist jeder Assistenzarzt in der Lage, selbstständig damit zu arbeiten“, so Schlüter-Brust. Da die Planung weniger als fünf Minuten dauert, lassen sich auch Notfälle ebenso präzise und sicher planen wie elektive Operationen. Als besonders wichtige, hilfreiche Funktionen haben sich die volumetrische Messung, die Erfassung des Abriebs und der prä- und postoperative Vergleich erwiesen. Auch die Messung des femoralen acetabulären Offsets, die Spiegelung der gesunden auf die dysplastische Seite und der Ganzbeinstand bei Knie-OPs ist ebenso wichtig wie beispielsweise bei der Planung von Umstellungsosteotomien am Knie und Hüftgelenk. Als Endoprothetikzentrum der Maximalversorgung muss die Klink alle Abweichungen von der OP-Planung exakt dokumentieren. Der Einsatz von „mediCAD Hip® 3D“ reduziert diese Abweichungen deutlich und hilft intraoperative Komplikationen zu vermeiden. Bei der Wechselendoprothetik ermöglicht die Messung der Pfannenantetorsion und der Pfanneninklination im 3D-Raum, Probleme der bisherigen Prothese zu erkennen.

Patientenindividuelle Prothetik

Seit Anfang 2017 nutzt die Klink die neuentwickelte Version von mediCAD Hip® 3D, die eine dreidimensionale Planung ermöglicht. Nach vier Monaten Einsatz dieses neuen Planungsmoduls zieht Schlüter-Brust eine überaus positive erste Bilanz: „Die dreidimensionale Planung ermöglicht eine bisher nicht vorstellbare Steigerung der Planungspräzision. Sie eröffnet den Weg zur CT-basierten dreidimensionalen Navigation und zur Auswahl patientenindividueller Prothesen.“ Wurde bisher unter den verfügbaren Prothesen die Bestmögliche ausgewählt, kann künftig die exakt passende Prothese erstellt werden. Prothesenhersteller können mittels der dreidimensionalen Planungsdaten eine „customized“ Prothese herstellen. Zusammen mit patientenindividuellen Schneideschablonen garantiert dies eine exakte Positionierung der Prothese an der geplanten und damit optimalen Position.

Kostenersparnis

mediCAD HIP® 3D ermöglicht zudem eine postoperative Kontrolle und Analyse – ein wichtiger Schritt zu noch mehr Sicherheit für den Patienten. Präoperativ öffnet die 3D-Planung künftig die Möglichkeit, auf Röntgen und CT zugunsten von MRT verzichten zu können. Präoperativ gelingt mit der dreidimensionalen Planung eine exakte Vermessung der individuellen knöchernen Situation des Patienten. Dies führt zu einer noch exakteren Prothesenplanung, einer Reduktion der Siebe und Instrumente und damit zu einer deutlichen Kostenersparnis. Beispiele für die höhere Planungsgenauigkeit sind die exakte Erfassung von Tilt, Torsion des Beckens und des Sacral Slope. „Auch wenn die dreidimensionale Planung manchmal statt bisher fünf Minuten nun bis zu zehn Minuten dauert, wiegen die Vorteile für den Operateur und den Patienten dies mehr als auf“, so die Überzeugung von Schlüter-Brust. Bei komplexen Operationen wie Umstellungs-OPs, bei Dysplasien oder Bechterew-Patienten werde dies noch deutlicher. „Kliniken, die sich heute mit der Auswahl einer Lösung zur digitalen OP-Planung beschäftigen, sollten unbedingt darauf achten, dass eine dreidimensionale Planung möglich ist“, so Schlüter-Brust. Mit der Produktpalette von mediCAD® werden hier alle Anforderungen der modernen OP-Planung erfüllt.

Endoprothetikzentrum der Maximalversorgung

Das St. Franziskus-Hospital ist ein akademisches Lehrkrankenhaus mit rund 300 Betten und 800 Mitarbeitern. Im Jahr werden durchschnittlich 15.000 Patienten stationär und 37.000 ambulant behandelt. Die Klinik für Orthopädie I unter der Leitung von Chefarzt Dr. Klaus Schlüter-Brust ist als „Endoprothetikzentrum der Maximalversorgung“ zertifiziert. Hier werden jährlich etwa 2.100 Patienten in 42 Betten stationär behandelt. Die digitale Planungssoftware ist auf acht PCs installiert, auf denen das fünfköpfige Team im Jahr etwa 600 prothetische Operationen digital plant, die sich etwa hälftig auf Knie und Hüfte verteilen.

mediCAD Hip® 3D – das leistungsstarke Tool für die Hüftchirurgie von morgen

Mit dem 3D-Modul mediCAD Hip® 3D aus dem Hause mediCAD Hectec werden dem Arzt völlig neue Möglichkeiten eröffnet die anatomische Beurteilung, Planungen und Messungen an der Hüfte durchzuführen und somit eine optimale revisionssichere OP-Vorbereitung zu realisieren.

Die wichtigsten Leistungsmerkmale dieses 3D-Moduls, die in enger Zusammenarbeit mit Spezialisten der Hüftchirurgie entwickelt wurden sind unter anderem: