Published, 28.08.2022

St. Franziskus Hospital in Cologne-Ehrenfeld

Digital surgery planning is an integral part of orthopedics – if nothing else, simply because

of the associated automatic complete documentation. The quality and time savings are

also much higher than planning with films and templates. Nonetheless, not all digitally

planned surgeries lead to a satisfactory result for the patient or the surgeon. The new option

of planning on a computer screen instead of in only two dimensions as before promises

great benefits. Planning in 3D means all exact mechanical/geometric parameters can be

included. This enables tangible patient-specific prostheses.

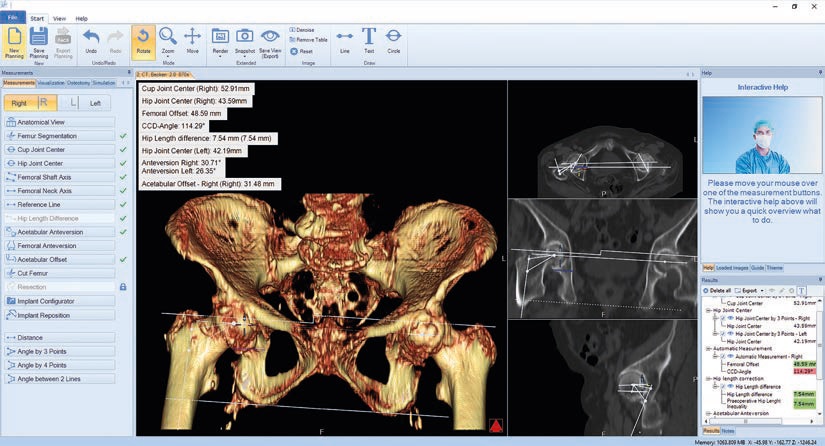

Digital surgery planning in 3D

The Orthopedics I Clinic at the St. Franziskus Hospital in Cologne-

Ehrenfeld has been using digital planning for entire orthopedic

prostheses since 2006. The mediCAD® software from the mediCAD

Hectec company has proven itself as a two-dimensional

planning tool. The company has been working on the development

of the program continuously since 1994. More than 3000

clinics and orthopedics practices around the world use it. The digital

solution includes all planning methods, documents all processes

correctly and covers all orthopedics surgeries – from hips

to knees and spine, and feet and ankles. mediCAD® is certified

and approved worldwide as a medical product. The basis is an

implant database containing articles from more than 140 manufacturers.

In addition to implants, surgeons also find a comprehensive

range of osteosyntheses for planning in mediCAD®. In

addition to the traditional proven 2D solution, mediCAD Hectec

now also offers the corresponding 3D module components:

mediCAD Hip® 3D, mediCAD Knee® 3D and mediCAD Spine® 3D

are already on the market, and the planning software modules

for shoulders and feet, and a mediCAD® web-based solution will

follow in early 2018.

At a glance:

The St. Franziskus Hospital in Cologne has been relying on

three-dimensional planning for hip surgeries with mediCAD Hip®

3D for quite a while now and is already planning on using the all

new mediCAD Knee® 3D module.

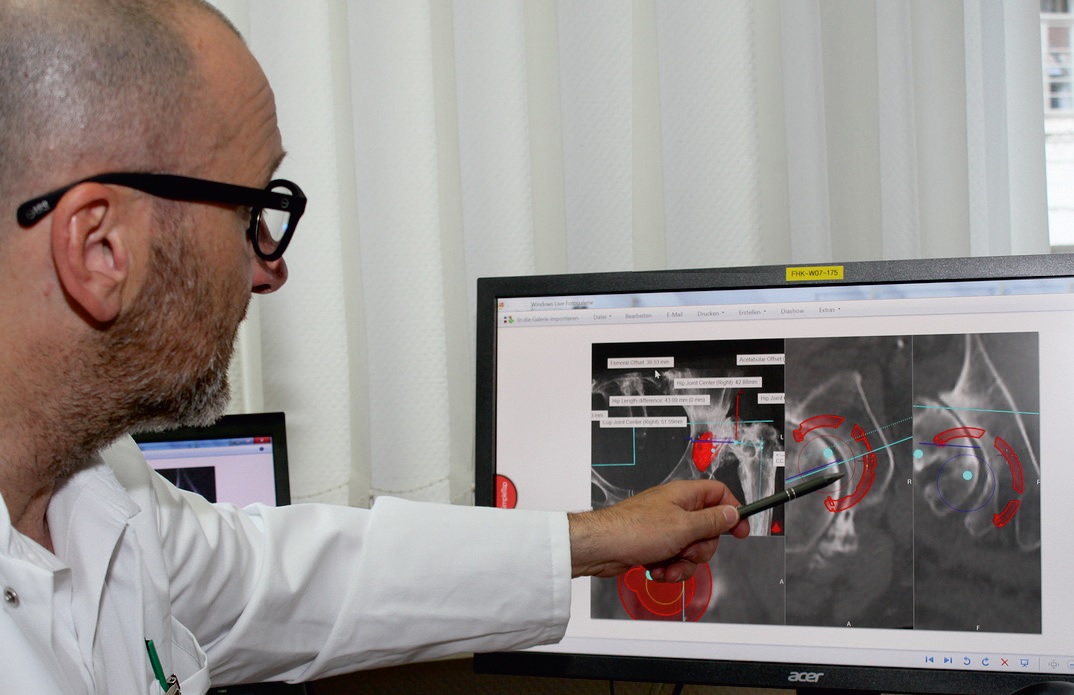

For Chief Physician Dr. Klaus Schlüter-Brust, the increase in

precision, which results in higher safety, is the best feature. At

the same time, the software is so user-friendly and self-explanatory

that even new users can very quickly create good plans.

„After working together on three plans, an assistant physician

can work independently,“ says Schlüter-Brust. Since planning

takes less than five minutes, emergency surgeries can also be

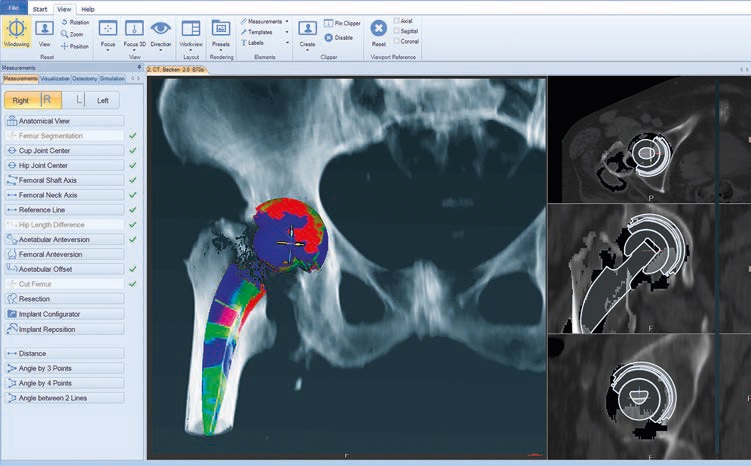

planned as precisely and safely as elective surgeries. Volumetric

measurements, detection of abrasions and the preoperative

and postoperative comparisons have proven to be particularly

important and helpful functions. The measurement of the femoral

acetabular offset, the comparison of the healthy side to the

dysplastic side and the overall leg condition with knee surgeries

is just as important as, for example, planning of an osteotomy

of the knee and hip joints. As an endoprosthetics center that

provides maximum care, the Clinic must precisely document all

deviations from surgical plans. Using mediCAD Hip® 3D significantly

reduces these deviations and helps avoid intraoperative

complications. In the case of replacement of an endoprosthesis,

the measurement of the socket antetorsion and socket inclination

in the 3D space enables the detection of problems with the

previous prosthesis.

Patient-specific prosthetics

Since early 2017, the Clinic has been using the newly developed

version of mediCAD Hip® 3D, which allows three-dimensional

planning. After four months of using this new planning module,

Schlüter-Brust has a very positive overall impression. „Three-dimensional

planning allows for an unprecedented increase in

planning precision. It opens up the path to CT-based three-dimensional

navigation and the selection of patient-specific prostheses.“

The best possible prosthesis was able to be selected until now, but

a prosthesis that is an exact match can be created in the future.

Prosthesis manufacturers can produce a customized prosthesis

using the three-dimensional planning data. Together with patient-

specific cutting templates, this guarantees exact positioning of

the prosthesis at the planned optimal position.

An endoprosthetics center that provides maximum care

St. Franziskus Hospital is an academic teaching hospital with

around 300 beds and 800 employees. In one year, an average of

15,000 patients are hospitalized and 37,000 patients are treated

on an outpatient basis. The Orthopedics Clinic I, headed by Chief

Physician Dr. Klaus Schlüter-Brust, is certified as an „Endoprosthetics

center providing maximum care.“ Around 2100 patients in 42

beds are treated here annually. The digital planning software is

installed on eight PCs, which the five-person team uses to digitally

plan around 600 prosthesis surgeries per year, which are distributed

about equally between knee and hip surgeries.

Cost savings

mediCAD HIP® 3D also enables postoperative control and analysis

– an important step towards even greater safety for the patient.

Used preoperatively, 3D planning will open up the possibility

of dispensing with X-rays and CTs in favor of MRIs in the future.

Three-dimensional planning enables accurate preoperative measurement

of the patient‘s specific bone situation. This leads to

even more precise prosthesis planning and a reduction in filters

and instruments needed, resulting in considerable cost savings. Examples

of the higher planning accuracy include the exact detection

of tilt, torsion of the pelvis and the sacral slope. Schlüter-Brust is

convinced of one thing: „Even if three-dimensional planning takes

up to ten minutes instead of five minutes as before, the benefits for

the surgeon and the patient more than make up for that,“ he says.

This becomes even more clear in the case of complex operations,

such as inversion and dysplasia surgeries or Bechterew patients.

„Clinics that are now dealing with a choice of solutions for digital

surgical planning should make sure that three-dimensional

planning is included,“ says Schlüter-Brust. The mediCAD® product

range fulfills all requirements for modern surgical planning.

mediCAD Hip® 3D – the high performance tool for the hip surgeries of tomorrow

With the new 3D module mediCAD Hip® 3D software from the mediCAD Hectec company,

physicians will have completely new options for carrying out anatomical assessments,

planning and measurements of hips, enabling them to achieve optimal, revision-proof

surgery preparation.

The most important features of this new 3D module, which was developed in close collaboration

with hip surgery specialists, include: