Published, 21.10.2022

What is 3D printing?

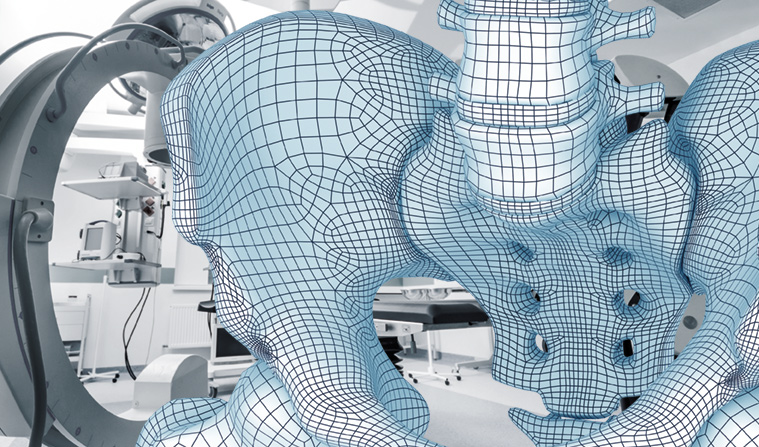

Three-dimensional (3D) printing works based on layers of materials that are gradually added to create 3D objects. This additive technology used in 3D printing is rapidly growing in the medical industry as well as in most sectors of our lives. The idea behind it is to create objects by controlled addition of material, as opposed to subtraction. Originally, 3D printing was developed in industrial and engineering fields for visualization purposes.

Playing a major role in personalized medicine helping medical staff select accurate therapies based on a patient’s characteristics. The correlation of personalized medicine and 3D imaging helps planning and to create solutions based on the natural structure of a specific tissue.

The current landscape of 3D printing use in surgery

3D printing technology is a success factor in orthopedic surgery thanks to the proving vital in preoperative rehearsal allowing surgeons to pre-determine approach, techniques, identify potential hazards, and how to overcome those in advance. This allows more personalized planning of critical surgery by explaining complex procedures in preoperative consultations.

Thanks to advanced patient education with 3D printing software the surgery team can perform a higher precision determined operation making it a worldwide success factor technology. Many surgical departments use 3D printing either as visual-tactile aids for preplanning surgery and even perform a complete test trial surgery. The main 3 topics that circle 3D printing applications in surgery are within the following three categories: surgical guides, implants, surgical 3D models.

Benefits of mediCAD® 3D printing in orthopedic joint replacement surgery

mediCAD® specializes in the preoperative planning of endoprosthetic procedures (joint replacement). For example, the most suitable prosthesis can be selected. This benefits the process significantly by diminishing trial-error situations.

A higher precision rate in a complex operation environment saves time and money. Less guesswork and more detailed facts and insights result in accurate surgery handling. More satisfied patients thanks to on-time recovery and better patient inclusion leads to a great clinic reputation.

The ability to plan preoperatively in detail and foresee challenges related to orthopedic joint replacement offers surgeons a more complete overview case by case. Good planning means less post-surgery work. Our customers, surgery teams across the world report higher confidence in the complete process and smoother, faster workflows.

How mediCAD® 3D Printing Services comes into place

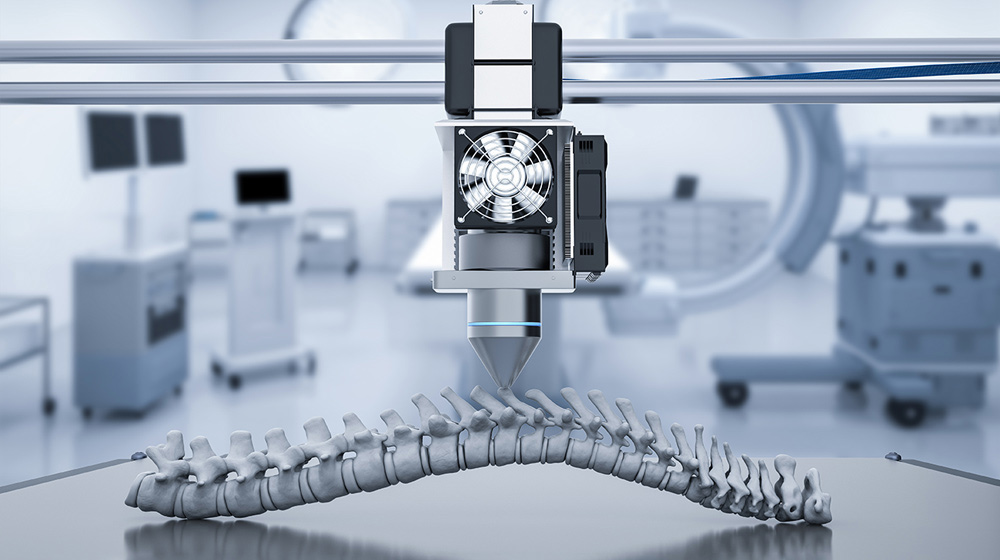

Preoperative planning enables a surgery team to test trial and position a variety of implants over the model, to locate the best anatomical fit and thus optimize beforehand. Now, 3D Printing from mediCAD® comes into place to materialize a patient-specific body part as an integrated subsequent step after digital pre-operative planning in mediCAD® 3D.

3D Printing by mediCAD® as part of the mediCAD® Services area offers the possibility to produce digital 3D models, e.g. of bones to be treated, true to scale as a model. .stl files, which can be exported e.g. from the mediCAD® 3D modules, serve as a basis. Image-based planning and medical 3D printing help surgeons across the world to completely personalize patient care. This unique level of predictability otherwise impossible to achieve convinces more and more customers in adopting our 3D planning and printing services as part of their surgery practices.

mediCAD® 3D Printing Advantages at a glance

How do mediCAD® 3D printing orders work step by step in a real case scenario?

Technical data:

Employing PolyJet printing process

– Sizes from 5x5x5 mm up to 480x380x190 mm possible

– Tolerance of +/-0,1 mm

– Surface quality Ra 5.5 / Rz 28

– Level of detail (minimum detail size to be finished): 0.4 mm

The future of surgery with 3D Printing software

3D printing software is programmed to be a leading tool in the future of operating rooms. The keyword that makes or breaks this future will always be “precision” in surgery. 3D printing software not only helps preoperative planning and foresee eventual issues but foremost it is a tool designed to achieve more precision in surgery. A cut is a cut and once executed there is little to nothing that can be repaired in the aftermath. Precision is key to experience positive outcomes in complex surgery.

3D models will play an increasingly significant role to develop a surgical plan, allowing surgeons to visualize the patient’s exact bone structure. 3D surgical printing is a milestone in surgical success offering data that is individually designed for a specific operation, optimizing the rate of success, and thus saving a lot of time and money with the aftermath.